Prefabricated Galvanized/Painted Light Steel Structure Shed Garage

Prefabricated Galvanized/Painted Light Steel Structure Shed Garage Advantage1.Cost saving and transportation convenient,

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | steel garage |

| Type of Steel For Building Structure | High-Strength Steel |

| Carbon Structural Steel | Q235 |

| Residential Wall Structure | Wall Support |

| Application | Steel Workshop, Steel Structure Platform, Steel Fabricated House, Structural Roofing, Frame Part, Steel Walkway and Floor, Steel Structure Bridge |

| Design | Free Design |

| Purlin | C.Z Shape Steel Channel |

| Keyword | Steel Structure Garage |

| Color | Red,Green,off-White or Customization |

| Material | Q235/Q235B/Q345/Q345b |

| Usage | Steel Structural Fabrication Construction/Worshop |

| Certification | ISO9001/BV/SGS/CE/En |

| Roof&Wall Material | Galvanized Steel Sheet ,EPS,Glass Wool,Rock Wool a |

| Main Steel Frame | Steel Frame |

| Product Name | Double Canopy Car Garage Carports |

| Surface | Painting and Hot DIP Galvanize |

| Transport Package | Standard Package |

| Specification | According to Customer Requirement |

| Origin | China |

| HS Code | 7308900000 |

| Production Capacity | 100000 Square Meters Per Month |

Product Description

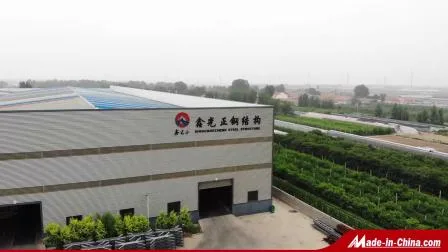

Prefabricated Galvanized/Painted Light Steel Structure Shed Garage

| Company Name | Qingdao Yili Steel Structure & Engineering Co.,Ltd |

| Main Product | Steel Structure, steel building, spot weld products,cattle panel,hog pen etc |

| Steel Frame | H .C ,Z ,T beam , Material grade :Q235B Q345B or as request. |

| Column & Rafter | Welded or Hot rolled H-section |

| Door | Rolled shutter door or Sliding door |

| Wall & Roof | EPS, Rockwool, PU sandwich, corrugated steel sheet |

| Window | Plastic steel or Aluminum alloy window |

| Surface | Shot blasting with anti rust paint or hot dip galvanize(More RAL color as per request) |

| Crane | 5MT, 10MT, 15MT, etc. |

| Production Lines | 2 production lines of light steel,heavy steel,space frame and tube truss. |

| Equipment | NC pipe cutting machine, CNC hydrauic shearing machine, Hydraulic sheet metal blending machine, Gantry submerged arc welding machine, Corrugated sheet molding machine, Shot blasting machine, Punching machine,Drilling Machine, Forging machine, H-section assembly machine,Straightener,H beam 3D drilling Machine etc. |

| Dimensions | Yours requirements |

| Quality Control | The third party ,SGS, ASIA INSPECTION all accept |

| Lead Time | 25-30 days |

| OEM&ODM | Service, We can quote according to your drawings |

| Pre-Sales Service | 1.Consultant service (Answering client's questions)2.Primary design plan(Free)3.Assisting client to choose suitable construction plan4.Price calculation5.Business&technology discussion |

| Sale Service | 1.Submission of support reaction data for foundation2.Submission of construction drawing3.Providing requirements for embedding4Construction Manual5.Fabrication & Packing6.Statistical table of material7.Delivery on time8.Other requirements by Clients |

| After-Sale Service | 1.Service of installation Supervision2.Instruction for using after installation completed |

| Our products:steel structural warehouse/workshop building, Agricultural building (Horse/cattle barn, poultry house), high rise steel building, heavy industrial steel structure building, car parking lot, steel structure aircraft hanger, school, office building, prefab house, container house, truss roof warehouses, sandwich panel, corrugated steel sheet, | |

Advantage1.Cost saving and transportation convenient, custom design available.2.The main beam and column are made of quality steel.3.Steel structure makes the house resist heavy wind of 220km/h and 8-grade earthquake.4.Easy assembly and disassembly several times without damage.5.Good environmental protection effect. Steel structure housing construction greatly reduces sand, stone and dosage of the ash. Most of the used materials are recyclable or degradable, little rubbish produced.6.Production according welding rules a = 0.7(1.0) x thickness of web.7.Continuous welding on both sides of each pieces.8.Own the hot dip galvanize zinc pool ourself,pool size:12.5x1.6x2m(LXWXD).9.Mark every beam on the bottom plate for being saw after being galvanized.10.Send pictures to the buyer by mail during products being processed and loaded in container.11.Near the Qingdao port,only need 1.5hour by car,the land transport cost cheaper.12.Near the Qingdao International port, only need 0.5hour by car, the client can visit us easily.

Related Products

-

![Prefabricated Plant/Hangar/Warehouse/Shed Steel Material Factory Engineered Sheet Structure Workshop Car Parking Carport Garage with Metal Frame]()

Prefabricated Plant/Hangar/Warehouse/Shed Steel Material Factory Engineered Sheet Structure Workshop Car Parking Carport Garage with Metal Frame

-

![Prefab/Prefabricated Industrial Factory Project Storage/Hangar Metal Frame Construction Warehouse Steel Structure Building Workshop for Export Installation]()

Prefab/Prefabricated Industrial Factory Project Storage/Hangar Metal Frame Construction Warehouse Steel Structure Building Workshop for Export Installation

-

![Prefabricated Steel Structure Warehouse Workshop Shed]()

Prefabricated Steel Structure Warehouse Workshop Shed

-

![China Industrial Steel Structure Building Prefabricated Workshop with Free Design]()

China Industrial Steel Structure Building Prefabricated Workshop with Free Design